OTHER PLANTS

SOFTENERS IONEXCHANGE RESINS

The limestone is present in the water, because this, crossing lands and cliffs of various nature, dissolves mineral salts as calcium and magnesium becoming “hard”, this hardness is normally measured in French Hardness (°F=10 gr x m³ of water). Unlike other impurities that see with naked eye, the limestone is invisible but with continuous action it obstructs and damages pipes, boilers, etc. In particular problems caused by the limestone can be so summarized: hard water needs a bigger quantity of detergent; it encrusts the fabric fibres making them rough and consuming them prematurely; it leaves an opaque limestone patina on the surface in stainless steel, chromium-plating, etc.; it alters the taste of the foods; it makes to waste thermic and electric power; the incrustations that are formed on the coils and the inner walls of boilers reduce considerably the efficiency of it with obvious problems of heat-exchange and consequent problems of maintenance.

Therefore, the softener is the device that solves, with the maximum use simplicity, the bound daily problems with the limestone and the obtained advantages are clear. Softening is based on the properties of ion exchangers which are designed to remove unwelcome ions replacing them with others. In this treatment there are employed ionexchange resins, that having a group works to yield (Na+) in exchange for ions Ca2+ e Mg2+ (hardness). The contact between ionexchange resins and the water happens in containers to pressure improperly called “filters”. These last ones are not mechanical filters, but indeed they must be fed with perfectly filtered water, because the operation of ionexchange resins can be hindered if substances in suspension in the water are deposited in the resin beds. Moreover the filters must be planned so as to assure an uniform water’s passage and regenerating through the resin bed. When these resins are in presence of water having 10% minimum of Na+, they have the tendency to yield ions Ca2+ e Mg2+ resuming sodium ion: regeneration’s phase. In conclusion we can say that softening, therefore, is carried out by strong >cationic resins, regenerated with one chloride solution of sodium. Resins’regeneration can happen in equi-current (same direction of use) or in counter-current (Paked Bed system) which let a saving of water and salt for the regeneration of 40%. Softening is recommended in those cases where hardness is the cause of incrustations or in the heating process, because temperature increase and salts of calcium and magnesium precipitate causing detrimental incrustations to boiler (temporary hardness).

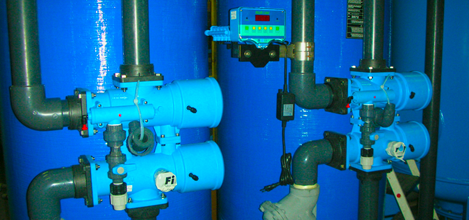

The systems come realized either in series version or based on the requirements of the customer. They are realized by modular elements pre-assembled and pre-tested on structure in stainless steel INOX AISI 304 (on the skid there are placed electric panel, pneumatic panel, supply pump system, flow meters of control capacities, filters, electric-pneumatic control group). The automation happens through centralized multifunctional valves (SIATA) or single pneumatic valves. The control of phases of working and regeneration is carried out through electronic standard programmer (SIATA) or controller by logic to programme (PLC).

INDUSTRIAL CENTRALIZED VALVE SOFTENERS

- Timed softeners (with automatic timed regeneration)

- Volume softeners (with automatic volumetric regeneration)

- Refill softeners (with automatic volumetric regeneration refilling two softeners)

INDUSTRIAL SINGLE VALVE SOFTENERS

- Timed softeners (with automatic timed regeneration)

- Volume softeners (with automatic volumetric regeneration)

- Refill softeners (with automatic volumetric regeneration refilling two softeners)

HOUSEHOLD SOFTENERS

- Monobloc centralized-valve softener with operator's cab, timed regeneration and electronic control unit. Optional: by-pass with hardener mixer built into the valve.

- Monobloc centralized-valve softener with operator's cab, volume regeneration and electronic control unit featuring closure valve used during regeneration.

- Monobloc centralized softener with operator's cab, volume/timed or only timed regeneration and electronic control unit. Optional: by-pass with hardness mixer built into the valve.

- Monobloc centralized softeners with operator's cab, volume regeneration, volume/timed or only timed regeneration and electronic control unit. With sterilization of resins during regeneration in compliance with the Health Ministry decree D.P.R. 443 of the 21712/90 and by-pass with built-in hardness mixer built into the valve.

- Dual body centralized-valve softeners with timed regeneration and electronic control unit. Optional: by-pass with hardness mixer built into the valve.

- Dual body centralized valve softeners with volume regeneration and electronic control unit with closure valve to use during regeneration.

- Dual body centralized-valve softeners with volume/timed or only timed regeneration. Optional: by-pass with hardness mixer built into the valve.

- Dual body centralized-valve softeners with volume, volume/timed or only timed regeneration and electronic control unit. With resin sterilization during regeneration in compliance with the Ministerial decree D.P.R. 443 of the 21/12/90 and by-pass with hardness mixer built into the valve.

- Two-column softeners in alternate automatic refill for 24/24-hour productions, volume regeneration and electron control unit.